The Problem

Hip revision surgeries are on the rise, but current implants fall short. Standard solutions often fail, while custom implants are costly and slow to produce, resulting in longer surgeries, more complications, and repeated revisions.

Current Limitations

- Rigid implants fail to conform to complex bone defects

- Poor biological integration leads to loosening

- Limited access to effective and custom solutions

- High revision rates and patient morbidity

- Extended surgeries and higher complication rates

Our Solution

A new standard for adaptability

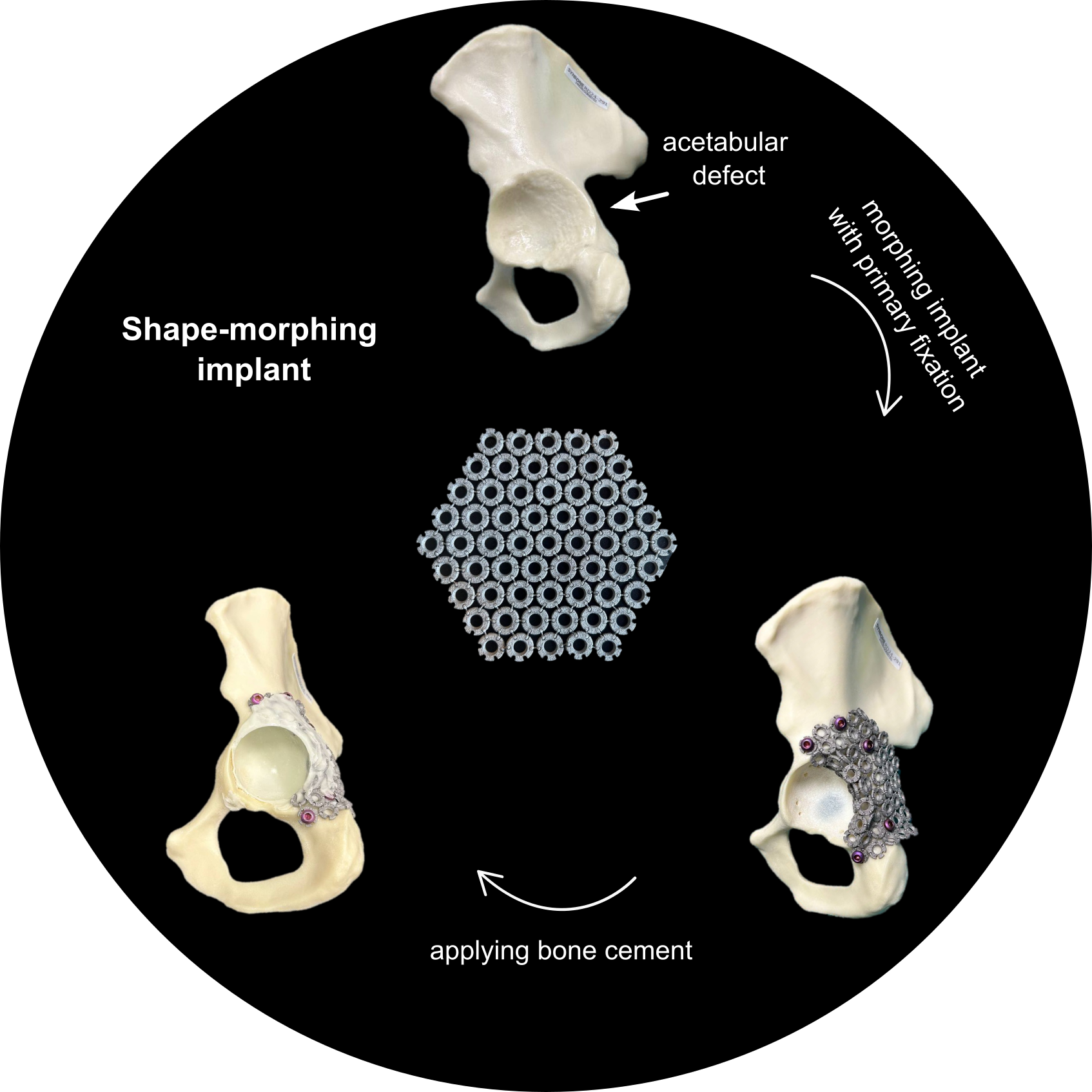

The OrthoClay Mesh

OrthoClay introduces a novel 3D-printed titanium mesh that is flexible, adaptive, and surgeon-friendly.

- A 3D-printed shape-morphing titanium mesh inspired by the concept of metallic clay, combining flexibility during implantation with rigidity after fixation.

- Conforms to any patient's anatomy without custom manufacturing.

- Once fixed with screws and cement, it becomes stable and load-bearing.

- Designed to support bone grafts and promote osseointegration.

- Enables surgeons to handle complex Paprosky IIIB-type defects with a single, ready-to-use solution.

How It Works

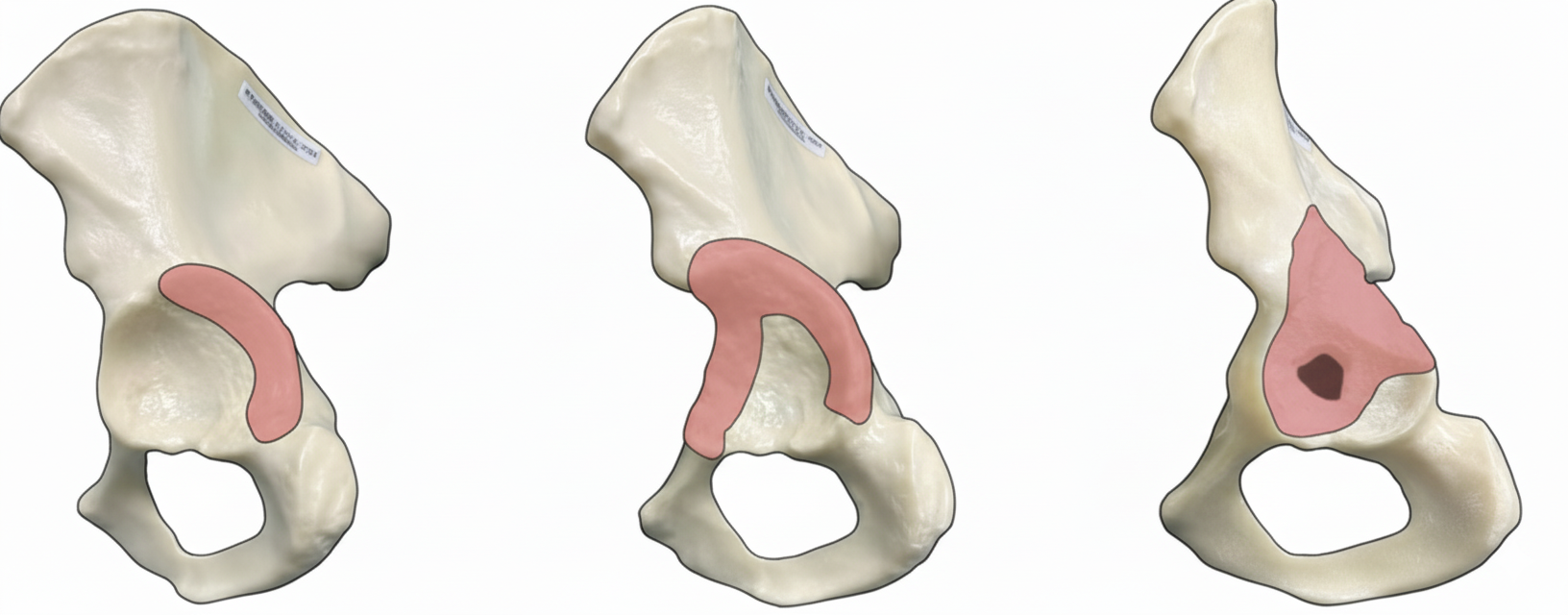

Step 1: Identify the Defect

The surgeon assesses the acetabular defect using imaging data to plan reconstruction.

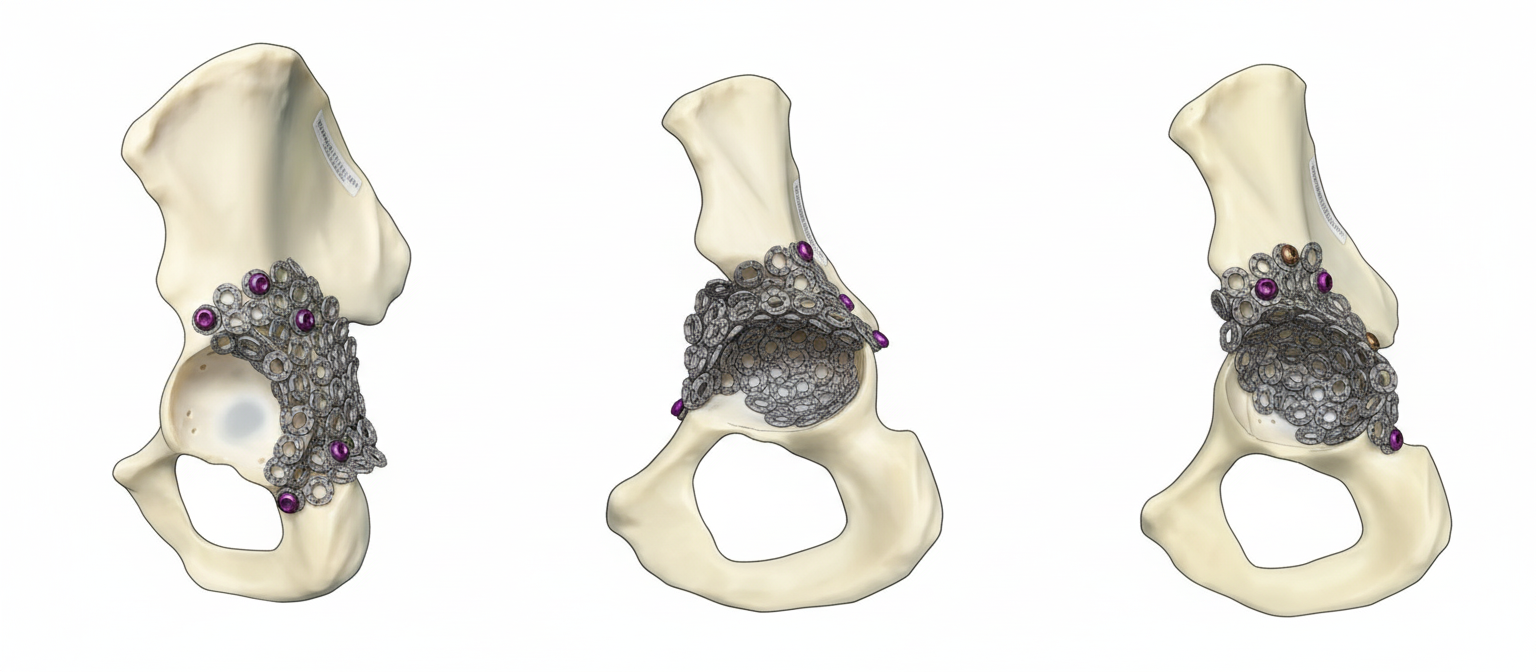

Step 2: Morph the Mesh & Fixate

The OrthoClay mesh is positioned, adapted to the bone surface, and fixed using screws for primary stability.

Step 3: Apply Bone Cement

Bone cement fills and locks the structure, providing stable fixation for the acetabular cup and long-term support.

Key Benefits

Patient-Specific Solution

Adapts to any defect without custom design.

Flexible Design

Conforms naturally to complex and irregular bone defects.

Enhanced Integration

Supports bone grafts and promotes osseointegration.

Reduced Surgery Time & Complexity

Fewer intraoperative adjustments.

Preserves Bone Stock

Minimal reaming, maximum reconstruction.

Available on Demand

Ready-to-use, scalable solution.

Clinical Impact

Designed for real surgical challenges.

Surgeon Benefits

- Freedom in screw placement

- Minimal intraoperative adjustments

- Comparable or shorter operation time than custom implants

Use Cases

- Suitable for acetabular reconstruction in revision THA (e.g., Paprosky IIIA–IIIB)

- Allows bone graft integration between and beneath mesh layers

- Simplifies surgical workflow while preserving bone stock

Preparing for Clinical Trials

We’re advancing OrthoClay toward clinical evaluation in collaboration with leading orthopedic centers. Our next milestone: validating safety and performance in patients undergoing complex hip reconstruction.

About Us

Founded by biomedical engineers and orthopedic surgeons, OrthoClay is on a mission to bring adaptable, accessible, and effective implants to orthopedic surgery worldwide.

Patient-Centered

Every decision we make prioritizes patient outcomes and quality of life

Innovation-Driven

We push the boundaries of what's possible in orthopedic technology

Collaboration

Working closely with surgeons to develop practical, effective solutions

Contact Us

Interested in learning more about OrthoClay? We'd love to hear from surgeons, investors, and healthcare partners.

Location

Delft, The Netherlands